Transforming Supply Chains: Exploring Digital Transformation Trends

Posted On

20.02.24 13:35

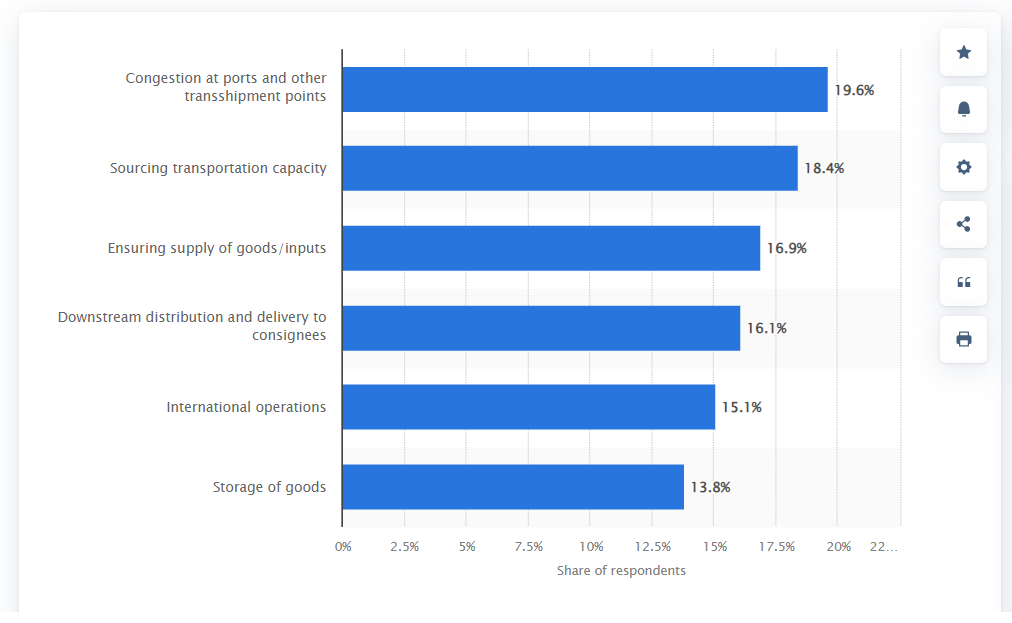

The global supply chain landscape and manufacturing industry are encountering significant hurdles as a result of various factors, including the surge in e-commerce, port congestion, and geopolitical conflicts, all contributing to major disruptions. According to Infosys, every market has witnessed double-digit growth in e-commerce, while the data from Hillebrand Gori indicates that the average waiting period due to port congestion was approximately 6.2 days in Q3 of 2023.

Amidst these challenges, organisations find themselves under immense pressure to uphold operational efficiency, optimise inventory management, and ensure timely deliveries to maintain customer satisfaction and competitiveness in the market. As highlighted by McKinsey, businesses are now expected to resolve and adjust supply chain issues within a matter of hours or days rather than weeks.

From the sourcing of raw materials to the delivery of finished products, companies are grappling with heightened complexities and uncertainties. Additionally, the growing awareness of climate change and environmental degradation has intensified scrutiny of supply chain practices. Companies are now compelled to reduce their carbon footprint, minimise waste, and embrace eco-friendly practices across their supply chains. Balancing sustainability goals with the need for operational efficiency presents a significant challenge, requiring innovative approaches to sourcing, production, transportation, and packaging.

In response to the multifaceted challenges facing the supply chain industry, companies are increasingly turning to the power of Industry 4.0 technologies and adapting digital transformations that focus on customer centricity, sustainability, risk mitigation and cost optimization. According to PWC’s 2023 Digital Trends in Supply Chain Survey, 86% of the executives believe that their company must invest more in supply chain technologies.

Supply chain technology encompasses both hardware and software solutions aimed at making supply chain processes more efficient. This includes a wide variety of digital technologies, ranging from physical equipment such as robotics and sensor-enabled devices to software designed to optimise the flow of data, predict trends, connect systems, improve logistics, or manage stock. Let's explore how organisations can revolutionise their supply chains with the latest innovations:

-

Use of Generative AI:

This technology has taken the world by storm. According to Accenture's Technology Vision 2024, 95 percent of executives agree that generative AI will profoundly transform their companies. The potential applications of generative AI across end-to-end supply chain networks are limitless. There are significant performance gains to be realised in various areas, from sourcing and planning to manufacturing, fulfilment, and after-sales service. Accenture's analysis suggests that 43 percent of all working hours in the entire supply chain function will be affected, with generative AI either automating activities (29%) or significantly enhancing the work of human employees (14%). Building upon previous advancements in artificial intelligence for supply chain management, such as control tower visibility, generative AI introduces a range of new capabilities:

Contextual understanding: It enriches forecasting and decision-making by providing contextualised insights derived from vast volumes of previously inaccessible unstructured data.

Conversational capabilities: This feature streamlines access to insights and creates new opportunities for automation through user-friendly interactions with AI agents using everyday language.

Content generation: Generative AI is capable of producing relevant and actionable content to augment and automate tasks in areas such as sourcing, procurement, customer service, and more.

The combination of generative and traditional AI in a platform can unlock a realm of possibilities for supply chain networks. This convergence holds the promise of expediting the time to gain insights and fueling data-driven decision-making, which in turn fosters enhanced supply chain sustainability, labour management, cost optimization, and customer-centricity. KPMG’s report suggests 50% of supply chain organisations will invest in applications that support artificial intelligence and advanced analytics capabilities.

-

Cloud Supply Chain Solutions

Another innovation in supply chain management is the adoption of cloud supply chains. By leveraging supply chain cloud computing, organisations integrate infrastructure and technology, thereby enhancing agility and data visibility. Moreover, harnessing the cloud can aid in cost reduction and facilitate the deployment of new applications.

Transport management solutions exemplify how the cloud can assist businesses in enhancing cost efficiency, reliability, and customer service. These solutions aid in the planning and scheduling of shipments, facilitating rate comparisons, tracking shipments, and monitoring sustainable supply chain operations. They are available as cloud-based services or as software packages hosted either on-site or in the cloud. Additionally, many companies access transport management information via dashboards provided by their shipping and logistics partners.

-

Internet Of Things

The Internet of Things (IoT) enables seamless data exchange within and between systems via the Internet, harnessing actionable insights from every phase of the supply chain. Its applications range from locating materials and servicing equipment to monitoring productivity and efficiency.

In 2013, the utilisation of smart sensors in supply chains numbered 20 million, providing live data feedback to those managing supply operations. By 2022, this figure skyrocketed to 1 trillion sensors, and Deloitte forecasts a potential deployment of up to 10 trillion sensors by 2030 (Deloitte). IoT technology plays a pivotal role in real-time tracking and monitoring of products, empowering organisations to make well-informed decisions regarding their supply chain management.

The IoT has witnessed exponential growth globally, with billions of devices deployed across diverse sectors, including smart homes and healthcare. Supply chains rank among the largest adopters of IoT technology, leveraging it for tracking goods in transit, monitoring warehouse inventory conditions, and automating tasks such as order picking and packing. A common feature of IoT implementations is the utilisation of compact electronic radio frequency identification (RFID) tags, which facilitate accurate item counting and tracking throughout the supply chain. Furthermore, geolocation applications integrate RFID, GPS, and high-speed wireless networks to offer companies real-time insights into merchandise flow, thereby aiding in the reduction of stockouts and shipping errors.

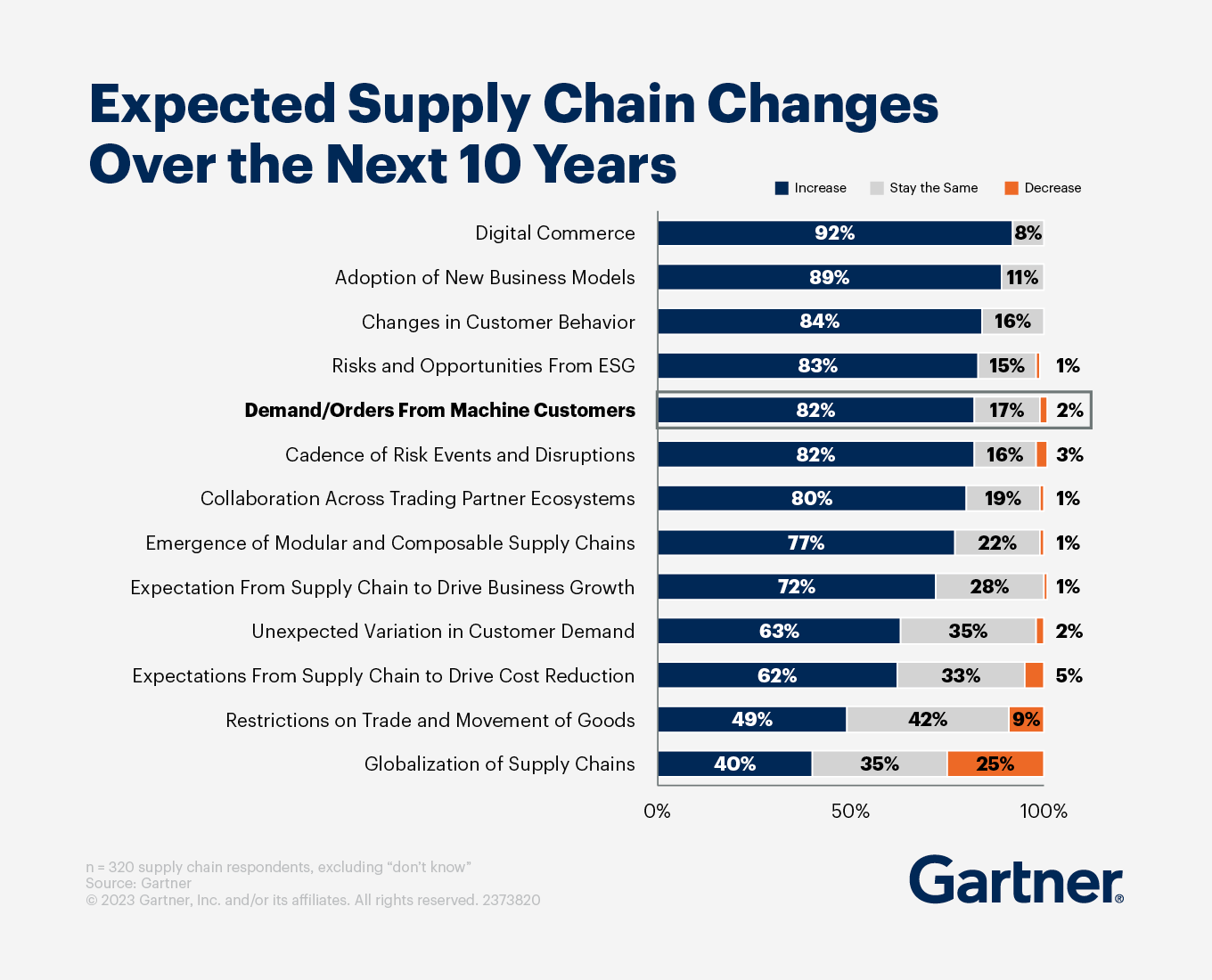

Source: Gartner

-

Blockchain Technology

Blockchain may appear to be an unexpected trend in supply chain technology, often associated with cryptocurrencies. However, its value lies in creating an immutable record of transactions, making it a reliable tool for enhancing trust in the exchange of goods.

The demand for transparency regarding the origin and trajectory of goods and materials is on the rise. Governments seek to ensure regulatory compliance among companies, while businesses aim to establish trustworthy supplier networks. Additionally, consumers are becoming more invested in the authenticity and sustainability of the products they purchase. In this context, blockchain technology emerges as a forward-thinking investment, offering a means to provide transparency and build trust throughout the supply chain.

Implementing blockchain in supply chain management poses a significant challenge: it takes the entire village. In many cases, a single company cannot implement blockchain to achieve traceability within its own supply chain. Instead, successful efforts often necessitate industry consortia-backed initiatives that benefit multiple competing partners. Collaboration among stakeholders is crucial for the widespread adoption and effective implementation of blockchain technology in supply chains.

In conclusion, the next decade promises significant shifts in supply chain dynamics, with demand from machine customers expected to become increasingly significant, driving over 20% of revenue. However, according to Gartner research, only a mere 15% of supply chains are currently equipped to effectively respond to this evolving demand.

According to PwC’s 2023 Digital Trends in Supply Chain Survey 83% of the executives suggest that their supply chain technology hasn't fully delivered expected results. At AppVista, we adopt a holistic approach and end-to-end integration of business and technology with Enterprise-wide platform transformations (EPTs). An effective enterprise platform serves as the technological foundation for digital transformation. It enables seamless data integration across corporate and operational systems, breaking down silos to enhance solution quality across channels and boost ROI. These platforms hold immense potential for transformation, yet their successful integration across manufacturing or supply chain organisations, demands dedicated investment and effort. However, relying solely on the IT department for transformation often leads to short-term results and lacks buy-in from stakeholders.

The key lies in transitioning from a technology-focused transformation to a technology-enabled business-wide transformation. This shift ensures sustainable growth and change by considering all stakeholder perspectives, adhering to budget constraints, and leveraging expertise from technology teams. This approach ensures that companies are able to improve their supply chain resilience and enhance their ability to respond swiftly to unexpected external disturbances. To understand more on the service, contact us at hello@appvista.digital.

For an optimal experience, please

rotate your device to portrait mode.